Tending Cell

Tending

Cell

Solutions

Tending Cells Solutions

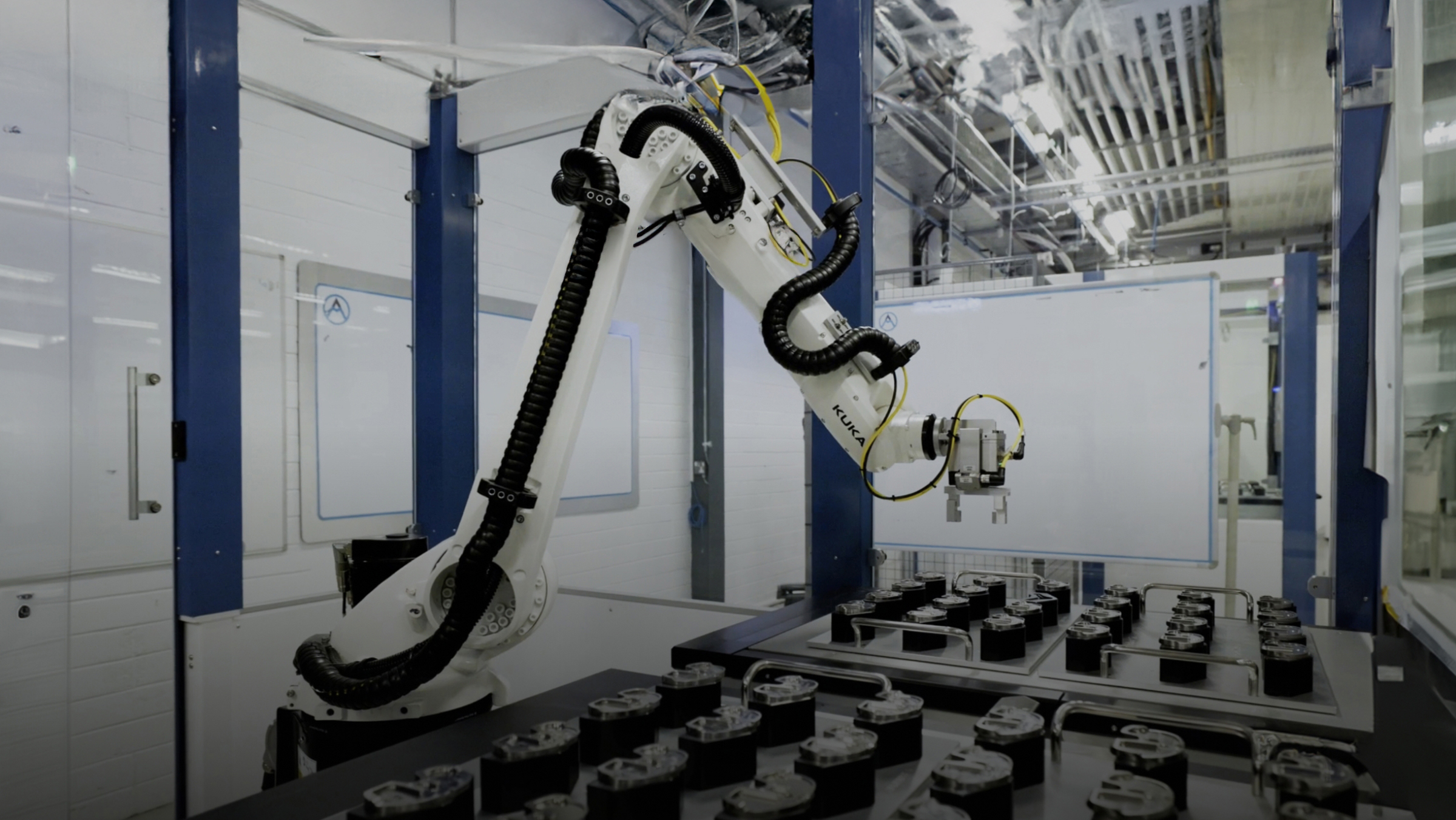

Automated robotics powering your manufacturing

Put automation at the heart of your production process with our proven, advanced machine tending cell, ideal for addressing repetitive loading, unloading, inspection, and processing tasks. Leverage the power of automation to increase your throughput, improve quality, and reduce the risk of error.

Our tending cell solution can be configured to integrate with your process equipment. Or talk to us about developing a custom process cell for your requirements.

Created from 30+ years

of Medtech expertise

-

Highly CustomisableIncluding payload, reach, and grippers.

-

Multiple Load FormatsChoose from drawers, conveyors, AIV and more.

-

Accurate TraceabilityTrack by product type and status.

-

User-FriendlyHighly intuitive interface.

-

Digital Factory SolutionIntegrate into your manufacturing database.

-

Increase EfficiencyReduced operating costs, higher throughput.

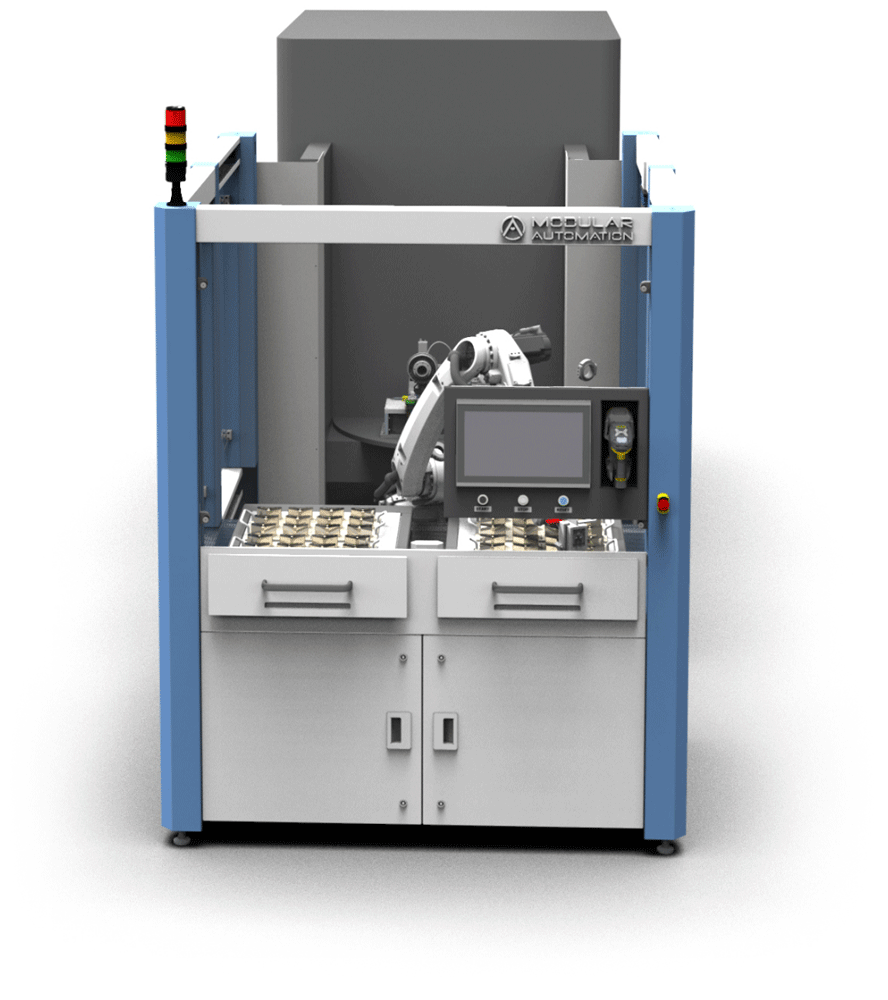

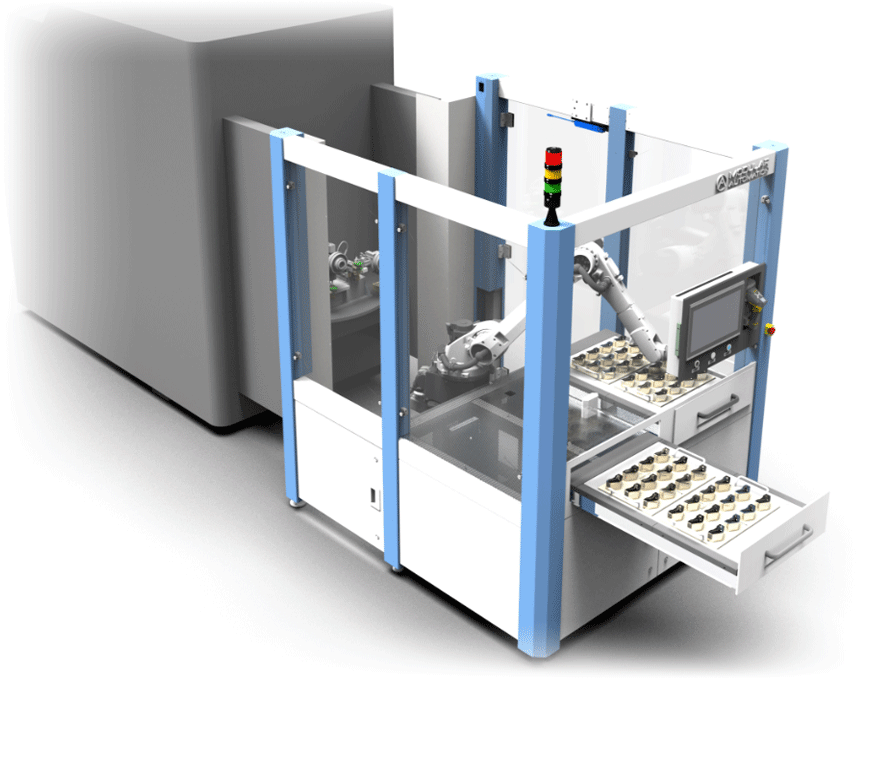

Key Features & Functionality

Precision engineering,

with super flexibility

Super flexibility

A core, off-the-shelf tending cell, with excellent customisation capacity.

Wide variety of load formats

Custom loading format options for greater flexibility.

Crystal clear traceability

Track, trace and record.

User-friendly

Highly intuitive and easy-to-use.

Customisable Features

Tailored to meet your

production needs.

-

Load formats - drawers, conveyors and AIV

-

Payload size – 4-8kg

-

Gripper types – 2-jaw, 3-jaw, vacuum

-

Safety perimeter guarding – physical or virtual

-

Reach – 1,420-1,840mm

-

EOAT – 1-up or 2-up

-

Digital integration – database and MES

-

Batch size

Features

Standard Features

Why Modular for Machine Tending?

A proven track record in advanced robotic automation delivery.

Immersed in automation.

For over 35-years we’ve planned, designed and build complex automation solutions. We’ve seen all the challenges first-hand, and know exactly how tending cells can be leveraged to deliver more efficient manufacturing.

Deep MedTech sector expertise.

We work with major, blue-chip, global manufacturers in the MedTech sector, partnering with them to deliver projects that drive their manufacturing processes. We have deep understanding of the sector, the regulations, the legislation and the practicalities of what’s needed.

Collaboration is in our nature.

We are a multi-disciplined team with the capability, knowledge, passion, ingenuity and confidence to work shoulder-to-shoulder with the world’s most advanced MedTech manufacturers.

A proven, highly-customisable cell.

Our machine tending cell is manufactured based on real-world production needs. We’ve allowed for a huge range of quickly and easily customisable features, ensuring our cell can seamlessly integrate with any production process.

Let’s discuss

your project

Get in touch for an exploratory discussion today. Let’s see how our machine tending cell can help improve your manufacturing.

info@modular-global.com